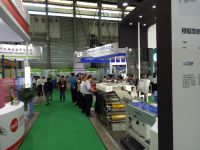

Today, I attended the fresh logistics Asia 2017 exhibition in Shanghai, a trade show for all elements involved in the logistics of fresh food delivery. Fresh food logistics are basically logistics with added requirements regarding temperature, delay, and safe handling of the transported items. The exhibits ranged from production machinery, delivery cars, fork lifts, and big and small containers, and storage systems over appliances like freezers, fridges, cooling systems and doors, registers to food and beverage products and supply offers. Like in case of the Intertraffic China 2017 exhibition I visited about ten days ago, the focus was more on hardware, with very cool exhibits and demonstrations.

For me as a researcher in optimization and mainly interested in the planning and the operations research making logistics and supply chains efficient, it was particularly interesting to see that even at such a rather hardware- and product-oriented fair, several exhibitors focusing on digitization, data management, and optimization of the logistics aspects were present, such as 晶链通. Yet, this subject was less prominent compared to the Intermodal Asia 2017 exhibition, maybe because large-volume container transport on a global scale over a heterogeneous network of carriers makes central data keeping an absolute requirement. Optimization and planning is enabled by the availability of data, it cannot work easily with Excel sheets. This is why I think that a technological evolution will probably start with better ERP, CRM, and warehouse management software, maybe as SaaS systems, for logistics and supply-chain management. Such systems have an immediate and obvious advantage for their users, as they enforce a clear work structure and allow for central statistical analysis. Based on the data collected, it becomes possible to move towards automated planning and optimization instead of starting with the latter.